Time: 2022-10-28

Source: TOOMOTOO

Author: TOOMOTOO

Click: 649 times

The filter element in the entire vehicle accessories of the forklift can be divided into the following types.

1. Forklift diesel filter:

The forklift diesel filter can also be called a forklift diesel electrical and forklift diesel filter element is one of the filter in the three filter of the forklift. The role of forklift diesel filter element is to filter out the harmful impurities and moisture in the fuel system, protect the normal work of the forklift engine, reduce wear, avoid blocking, and increase the life of the forklift engine. The filter material of the forklift diesel filter is mostly filter paper, and there are felt or polymer materials. The filter element of the gasoline filter is mostly filter paper, and nylon cloth and polymer materials are also used.

2. Forklift Air Filter:

The forklift air filter can also be called a forklift air filter element and forklift air grid. Its main function is to install the inlet of the forklift gasification device to remove the suspended dust and other unclean substances that enter the carburetor air. Extend the service life of the forklift engine accessories.

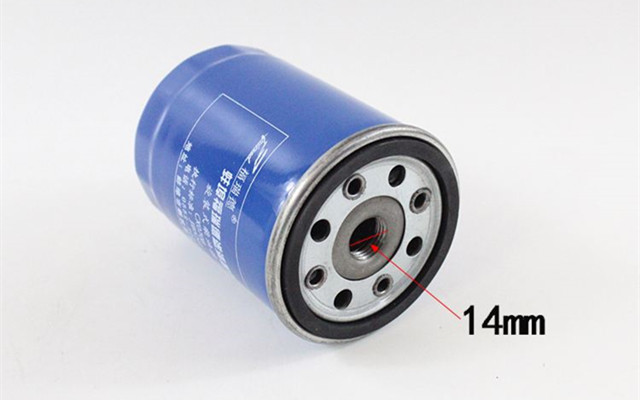

3. Forklist oil filter:

The forklift oil filter can also be called a forklift oil grid. The role is to remove impurities such as dust, metal particles, carbon sedibles, and cigarette particles in the engine to protect the engine. The forklift oil filter is divided into the division of the oil collection filter, the oil coarse filter, and the oil fine filter.

4. Forklift filter box filter element:

The forklift filter box filter element is a device installed in a forklift shot. The gearbox filter is generally used to filter the oil pollution in the gearbox.

5. forklift hydraulic filter element:

The forklift hydraulic filter element is mainly used in hydraulic systems to filter the solid impurities inside in the internal operation of the hydraulic system. It is mainly installed on the oil -absorbing road, the pressure oil road, the oil return road, and the bypass, and the separate filtration system installed on the hydraulic system. During the use of industrial hydraulic oil during use, some reasons will be mixed into some impurities. The main impurities are mechanical impurities, water and air, etc. These impurities will cause corrosion to accelerate, increase mechanical wear, reduce work efficiency, make hydraulic oil oil During the degeneration of the product, the service life of the equipment will cause oil circuit blockage and cause production accidents in severe cases. Solid oil filtration of concrete conveyor pumps, hydraulic oil filtering of construction machinery, and filtering of hydraulic stations in hydraulic stations.

<< Previous page

Next page >>

LINKS:

Harber Metal